SKILT Rotary hot melt glue labeling machine is an efficient and automated packaging device designed for precise label application on various containers (e.g., glass bottles, plastic bottles, metal cans). It uses hot melt adhesive as the bonding agent and features a rotating worktable for multi-station synchronous operation. Integrating feeding, gluing, labeling, pressing, and discharging functions, it is widely used in food, beverage, pharmaceutical, daily chemical, and cosmetics industries .

Core Structure:

Rotary Conveying Platform: Equipped with a high-precision indexing plate or servo-driven turntable for equidistant intermittent rotation, ensuring coordinated actions across stations .

Hot Melt Adhesive Supply System: Consists of a melting tank, hoses, gear pumps, and nozzles/roller applicators for precise control of glue volume and application position .

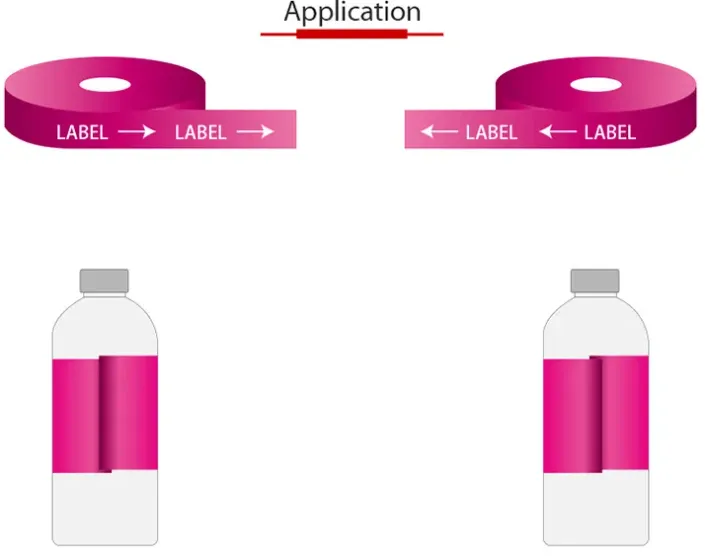

Label Feeding Mechanism: Uses reel-type unwinding with tension control and sensor correcting deviations to ensure stable label delivery .

Labeling Execution Mechanism: Transfers labels accurately to containers via robotic arms, suction heads, or swing arm devices .

Label Pressing Device: Utilizes rubber rollers or pneumatic pressure heads to enhance bonding strength .

Control System: Based on PLC+HMI architecture, supporting parameter setting, fault diagnosis, and line integration .

Working Process:

Containers enter the positioning station → Turntable moves products to the gluing station → Hot melt adhesive is evenly applied to label backs → Labels are transferred to the labeling station → Containers rotate to complete labeling → Pressing mechanism secures labels → Products exit to the output conveyor .

Advantages

1.High Efficiency and Productivity:

Multi-station parallel operation (typically 6–20 stations) enables simultaneous labeling of multiple products. For example, a 20-station model running at 60 rpm achieves a theoretical capacity of 720 units/minute, outperforming linear labeling machines .

2.Precise and Consistent Labeling:

Servo-driven indexing plates ensure positioning accuracy within ±0.05mm. Photoelectric sensors and visual calibration systems eliminate feeding errors, while precision metering pumps control glue volume to prevent bubbling or edge lifting .

3.Strong Versatility:

Adaptable to containers of various shapes (round, square, oval) and sizes by replacing fixtures and adjusting parameters. Supports front, back, double, or wrap-around labels, compatible with paper, synthetic paper, and film materials .

4.Superior Adhesion Performance:

Hot melt adhesive offers high initial tack, fast curing, temperature resistance, and solvent-freeEnvironmental characteristics. Labels bond instantly without drying, maintaining adhesion in cold or humid environments (e.g., cold-chain beverages) .

5.Stability and Easy Maintenance:

Key components (e.g., SMC pneumatic parts, Mitsubishi/Panasonic servo systems) ensure reliability. Modular design allows independent disassembly of gluing and labeling units, with HMI providing fault codes for quick troubleshooting .

6.High Intelligence and Integration:

Enables joint control with filling, coding, and cartoning machines. Supports remote monitoring via MES/SCADA systems for data collection and smart scheduling .

7.Low Comprehensive Cost:

Despite higher initial investment, high throughput reduces per-unit labeling costs. Efficient glue usage and minimal downtime lower long-term operational expenses .

Typical Applications

Beverage Industry: Labeling mineral water, tea, and juice bottles .

Pharmaceuticals: Applying batch and instruction labels to oral liquid and infusion bottles .

Daily Chemicals: Automated labeling for shampoo, shower gel, and laundry detergent bottles .

Cosmetics: Precision labeling for perfume and cream bottles .

Industrial Products: Weather-resistant labels for lubricant barrels and chemical cans .

In summary, the rotary hot melt glue labeling machine is a critical asset in modern packaging lines, valued for its efficiency, precision, stability, and intelligence across industries with stringent labeling and productivity requirements .

|

Yield(pcs/hour) |

3000~26000 /hour |

|

Labeling accuracy |

±1mm(Except for package factors) |

|

Label loss rate |

≤1‰ |

|

Suitable label size |

L: ≤ 370mm , H: ≤ 200mm |

|

Max label roller outer Dia |

520mm |

|

Suitable bottle size |

W: ≤100mm,H:≤310mm |

|

Suitable bottle |

Round, square , flat bottles, irregularly shaped |

|

Label material |

OPP, pearlized film, or composite paper |

|

Glue |

hot melt glue , add glue temperature : 120-170° |

|

Power |

30KW |

|

Air supply |

0.6Mpa Consumption : 0.6M3/min |

|

Speed control method |

Infinitely variable speed control |

|

Press bottle head quantity |

20 |

|

Machine size |

5000×3200×2500mm |

|

Name |

Brand |

|

PLC |

B&R |

|

Touch screen |

B&R |

|

Label cutting drum servo motor |

B&R |

|

Put label roll plate servo motor |

B&R |

|

servo driver |

B&R |

|

Spindle drive servo motor |

B&R |

|

Rubber roller servo motor |

B&R |

|

Separate Bottle screw servo motor |

B&R |

|

Dual-axis driver |

B&R |

|

Single-axis driver |

B&R |

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)