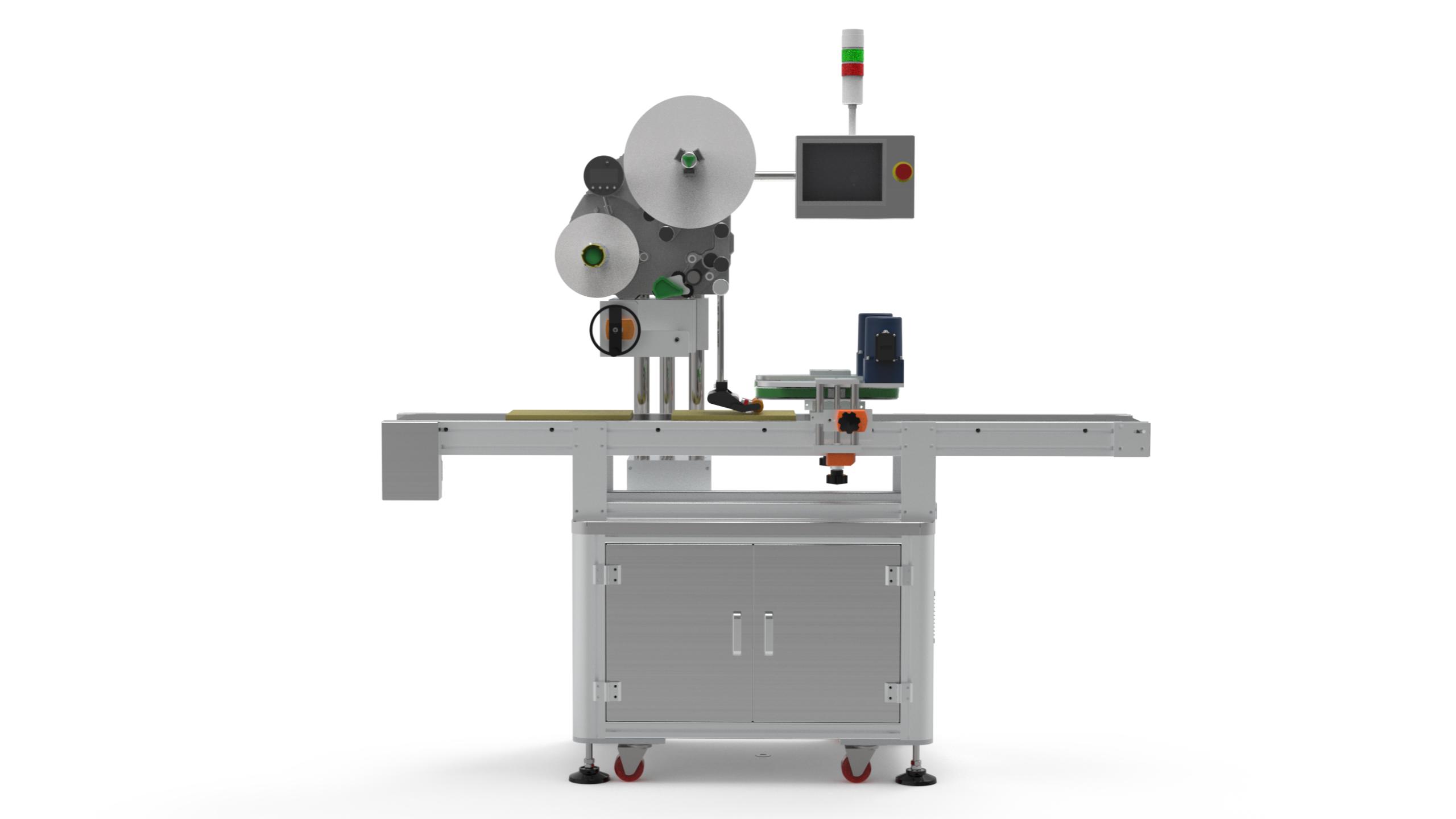

Labeling machine top labeler DPM solution :

1. The DPM series for top labeling is compact, versatile and reliable, It has been designed based on SKILT modular kit,meaning quickly ready for use.

2. No matter the product surfaces are smooth flat uneven or recessed, the DPM ensures a high throughput in all cases.

3. Machine can be supplied with a variety of conveyor belt dimensions, which means they can be configured for a huge range of applications.

Machine Features Introduction :

1. Labeling engine with SKILT servo control system and German Novexx ALS204 optional;

2. Easy to integrate into any kind of production line ;

3. Easy to integrate printers for variable labeling ;

4. Can be combined with the reliable bottom labeler, labeling on top and bottom two surface ;

5. Infeed and outfeed turntable optional ;

| No | Name | Brand |

|---|---|---|

| 1 | PLC control system | SIEMENS |

| 2 | Touch-screen | SIEMENS |

| 3 | Labeling engine servo motor/driver | Panisonic & German NOVEXX |

| 4 | Check label sensor |

German LEUZE |

| 5 | Frequency converter | SIEMENS |

| 6 | Check product sensor | Japan KEYENCE |

| 7 | Main conveyor motor | German JSCC |

| Model | DPM-A & DPM-ALS204 |

| Driving Model | Servo control system & German NOVEXX |

| Label material | Self-adhesive sticker, opaque or transparent label |

| Yield(pcs/min) | 20-300pcs/min |

| Suitable label size | L:10-300mm,H:10-300mm |

| Suitable labeling objects size | L: 40-380mm , H:40-350mm |

| Voltage | 110V/220V/380V |

| Machine size | 1800(L)× 800(W) × 1500 (H) mm |

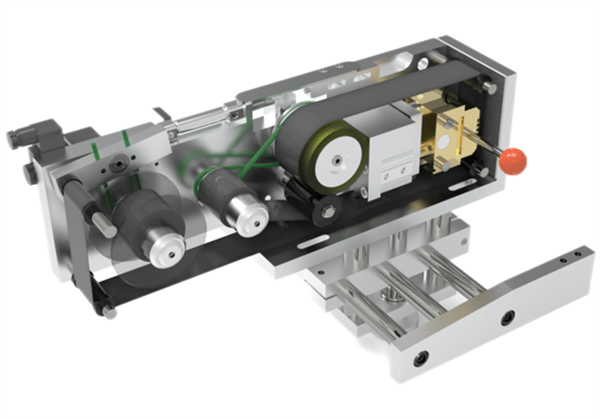

1. Printer device , printing date and batch number on labels.

2. GERMAN NOVEXX Labeling engine

① Machine with two years warranty;

② Supply operation training for client workers ;

③ If with quality problem, provide technical support and supply wearing parts timely .

④ Range experienced engineer come to client company for installation;