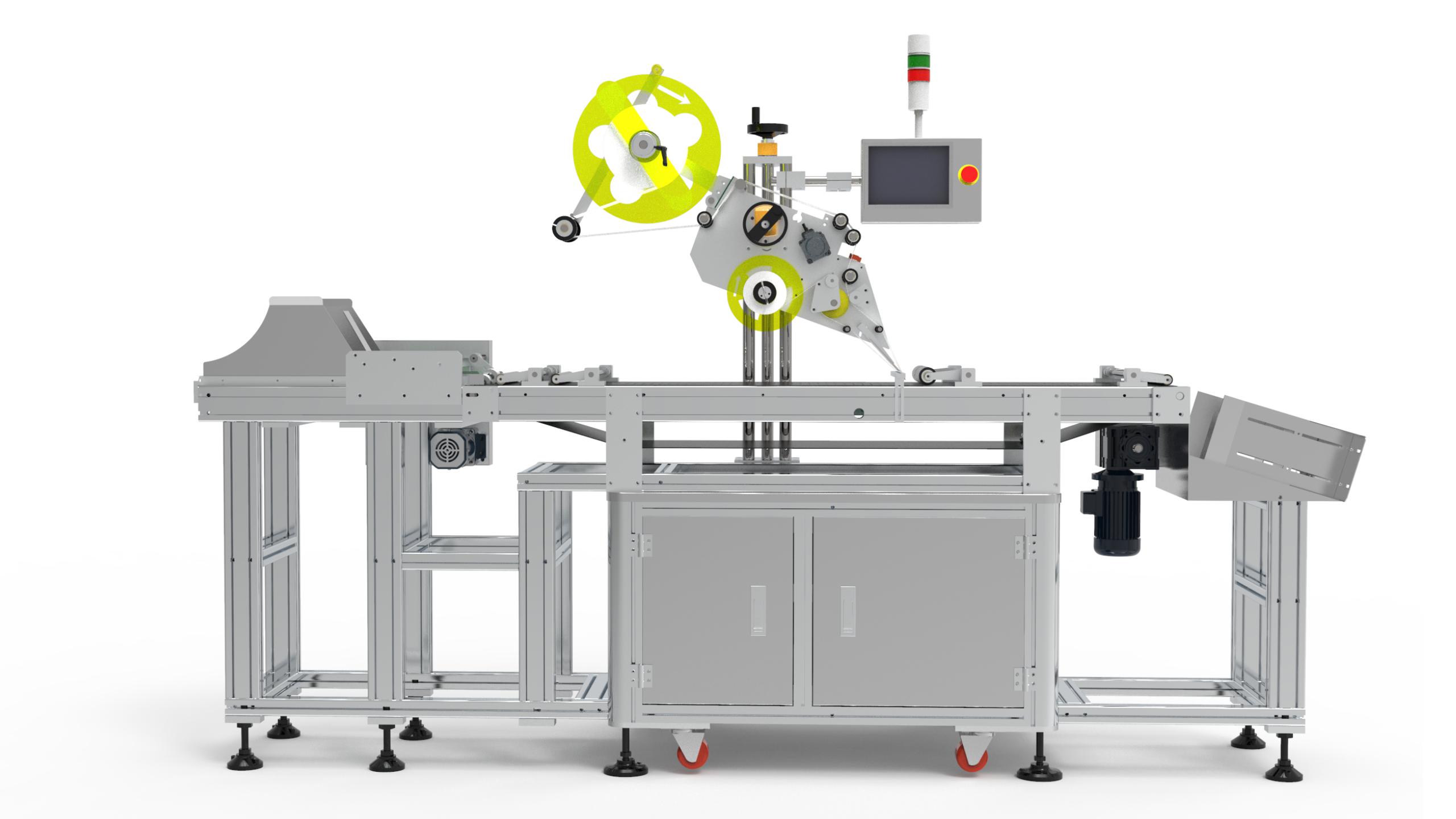

Auto Paging & Labeling Machine Features Introduction

1. SKILT PM-DPM Series Label Applicator applies labels onto flat surfaces featuring with loading platform and high friction belting.

2. With different kinds auto outfeed for choose, to suit for client differnet kinds products, such as zip bag, pouch, food bag, card;

3. This series labeling machine can store up to 20 different product profiles consisting of different label sizes,speed and location of label placement within the machines memory for quick recall during changeover.

WHAT DOES IT HAVE?

1. Novexx Label Head Model ALS204 for 130′ or 40m/minute dispense speed

2. Label Counter, Missing Label Detection and Auto Teach

3. +/- 1 mm Label Placement Accuracy

4. High Friction Conveyor Belt

5. Speed Encoder to lock label dispense speed with conveyor speed

6. Loading Platform for speedy loading of bags. (100+ pouches per minute)

7. Fully adjustable guide railing for quick changeover

WHAT COULD IT HAVE?

1. Up to 6″ Label width with the ALS206 label head

2. Up to 9″ Label Width with the ALS209 label head

3. Different kinds outfeed collection way for choose

4. Hot Stamp Coder or Inkjet Coder

5. Online Print Applicator

6. One more applicator for two stickers on bags

7. Conveyor width and length modification

MACHINE FUNCTION INTRODUCTION

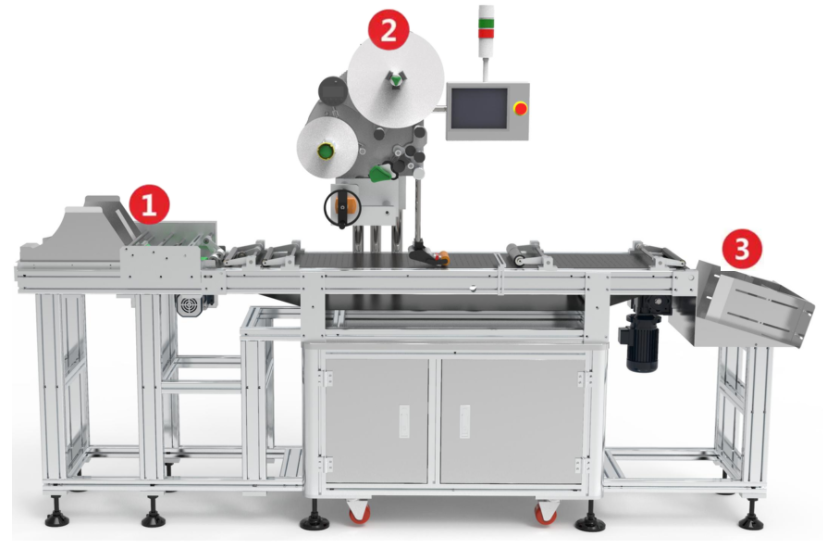

1. Feeder : Paging device, can put labeling objects (for example box) into feeder device, delivery out one by one;

2. Labeling : When bag delivery to the labeling position, past sticker on bag surface directly;

Labeling engine with SKILT Servo control and German Novexx ALS204 for choose.

3. Collection : After finish labeling, delviery to the end part for collection. Collection with different kinds for client choose.

| No | Name | Brand |

|---|---|---|

| 1 | PLC control system | SIEMENS |

| 2 | Touch-screen | SIEMENS |

| 3 | Labeling engine Servo motor | Panisonic & German NOVEXX |

| 4 | Labeling engine Drive | Panisonic |

| 5 | Frequency converter | Delta |

| 6 | Check bag sensor | Japan KEYENCE |

| 7 | Check opaque label sensor | German Leuze |

| Check opaque and transparent label sensor | GSU | |

| 8 | Conveyor motor | JSCC |

| Model | PM-DPM-A & PM-DPM-ALS204 |

| Driving Model | Servo system & German Novexx |

| Label material | Self-adhesive sticker, opaque or transparent label |

| Yield(pcs/min) | 50-200pcs/min |

| Suitable label size | L:15-300mm,W:15-300mm |

| Suitable bag size | L:20-300mm , W:30-300mm |

| Voltage | 110V/220V/380V |

| Machine size | 2200(L)× 800(W)× 1600 (H) mm |

1.Visual inspection system :

After labeling, bags delivery to visual inspection system, camera start working and detect labeling accuracy, unqualified product will be take out into waste box;

2. Collection device:

With double layer collection device and conveyor collection device for optional ;

3. German NOVEXX Labeling engine

① Machine with two years warranty;

② Supply operation training for client workers ;

③ If with quality problem, provide technical support and supply wearing parts timely ;

④ Range experienced engineer come to client company for installation;