SKILT Unique Horizontal Way Labeling Solution

PWM Series horizontal wrap around automatic labeling machine suit for non-stable cylindrical products, such as ampoule,carpule ,tubes,pens,syringes,lipsticks,smoke flares,cartridges and so on.

The products are labeled all around. The lying products reach the labeling station via a clocked roller conveyor belt, which fixes the label on the circumference. The system convinces with the highest positioning accuracy.

Machine Features

1.Has few moving parts, adjustments are easily made, changeovers easy.

2.Angled roller conveyor made depends on labeling objects shape and size, ensures labeling accuracy.

3.Auto feeder design and slanted conveyor made from special engineering plastic roller, potential damage to fragile containers are minimized.

Additional modules

1. The system can be expanded to include label printing systems such as thermal transfer printing systems, thermal inkjet devices (TIJ), continuous inkjet systems (CIJ) or hot stamping devices,TTO module.

2. Optional vision systems guarantee quality criteria such as the presence, correctness of print data, label placement on your products and ensure that complaints are settled right from the start.

Machine Detail Function Show

| No | Name | Brand |

|---|---|---|

| 1 | PLC control system | SIEMENS |

| 2 | Touch-screen | SIEMENS |

| 3 | Servo motor | PANISONIC |

| 4 | Servo drive | PANISONIC |

| 5 | Frequency converter | DELTA |

| 6 | Check labeling object sensor | Japan KEYENCE |

| 7 | Check opaque label sensor | German Leuze |

| 8 | Main transport motor | JSCC |

| Model | PWM-A & PWM-ALS204 |

| Driving Model | Servo system & German Novexx |

| Labeling way | Horizontal way |

| Label material | Self-adhesive sticker, opaque or transparent label |

| Yield(pcs/min) | 50-400pcs/min |

| Suitable label size | L:10-100mm,H:10-150mm |

| Suitable tueb size | Diameter: 10-30mm |

| Voltage | 110V/220V/380V |

| Machine size | 1800(L)× 800(W)× 1500 (H) mm |

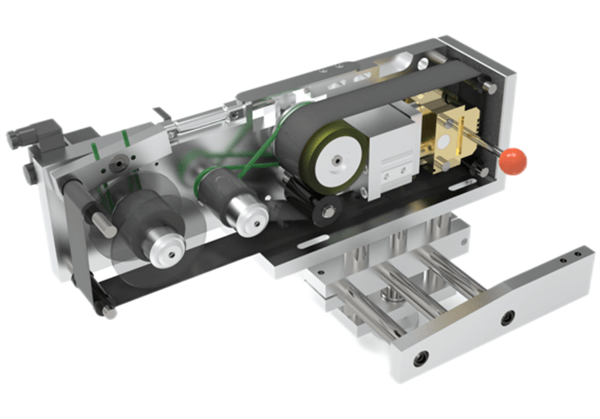

1. Printer device

Thermal transfer printer , printing date and batch number on labels.

2. German NOVEXX Labeling engine

① Machine with two years warranty;

② Supply operation training for client workers ;

③ If with quality problem, provide technical support and supply wearing parts timely .

④ Range experienced engineer come to client company for installation;