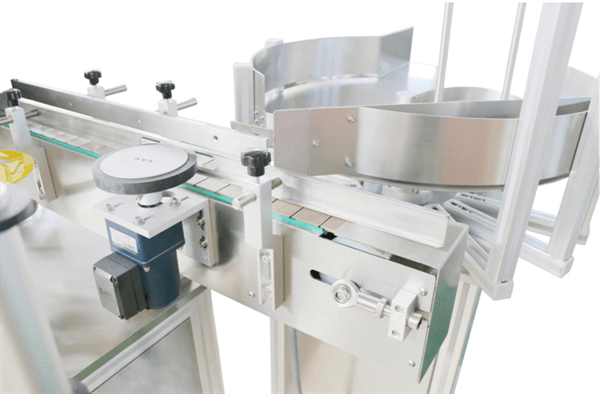

High performance wrap-around labeling system l Vial labeling

With the continuously rotating starwheel, up to 500 pcs/min can be labeled.

Optional Function :

Infeeder and Outfeeder Rotary table in different size ;

Check or rejection of fallen products ;

Code checking function ;

Printers : Various hot-foil, thermal transfer and laser printers (optional)

| No | Name | Brand |

|---|---|---|

| 1 | PLC control system | SIEMENS |

| 2 | Touch-screen | SIEMENS |

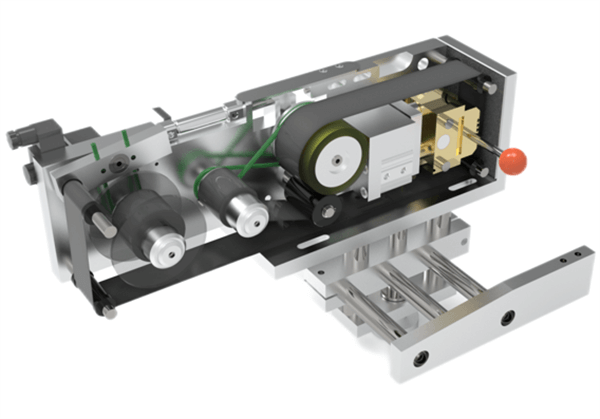

| 3 | Labeling engine | GERMAN NOVEXX |

| 4 | Frequency converter | DELTA |

| 5 | check bottle sensor | Japan KEYENCE |

| 6 | Check opaque label sensor | German Leuze |

| Check opaque and transparent label sensor | GSU 14B/66.3-S12 | |

| 7 | Main transport motor | JSCC |

| Model | PLM-HZ-A and PLM-HZ-B |

| Product specifications: | Cylindrical,vial,Ampoule |

| Driving Model | Servo system & German Novexx |

| Label material | Self-adhesive sticker, opaque or transparent label |

| Yield(pcs/min) | 100-500pcs/min |

| Suitable label size | L:10-300mm,H:10-200mm |

| Suitable bottle size | Diameter: 20-100mm |

| Voltage | 110V/220V/380V |

| Machine size | 2400(L)× 1600(W)× 1600 (H) mm |

1. Printer device , printing date and batch number on labels.

2.Turntable

If machine not connect with production line, suggest choose turntable more convenient for operation.

3.German NOVEXX Labeling engine

① Machine with two years warranty;

② Supply operation training for client workers ;

③ If with quality problem, provide technical support and supply wearing parts timely .

④ Range experienced engineer come to client company for installation;