Wrap-around labeling solution

- A large area of application for round bottle/jars/cans labeling,usually labeled wrap around ;

- In pharmaceutical is indispensable for vial labeling, bill bottle labeling ;

- Labeling of cosmetics, shampoo bottle wrap around labeling, detergent round bottle labeling;

- Confectionery and good labeling from jam in jars to cereals in cans labeling wrap around ;

- Chemical products paint round cans labeling and much more ;

Optional Features

- Turntable at infeed and outfeed for round bottle labeling machine ;

- One more labeling engine for machine not stop working when change label roll;

- Visual camera detection function for printing content ;

- Sensor for label use up, machine alarm ;

- Sensor for product lack of label , tick it out ;

- Machine hight can customized depends on client production line.

Machine Detail Function

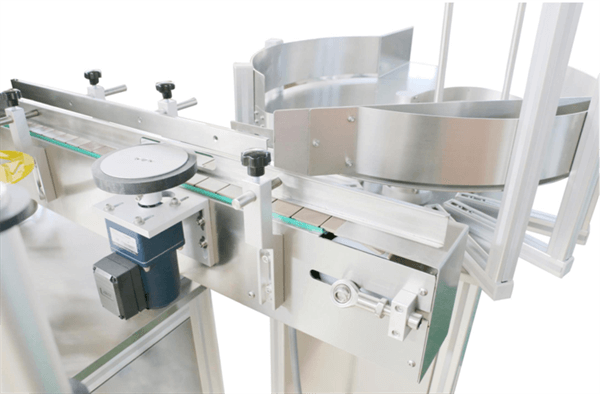

Part1: Auto infeed turntable, diameter with 600mm 800mm 1000mm optional.

Part2: Labeling part,rolling label device made depends on client products Max size,labeling engine with SKILT servo control system and German Novexx ALS204 optional.

Part3: Auto outfeed turntable for collection.

| No | Name | Brand |

|---|---|---|

| 1 | PLC control system | SIEMENS |

| 2 | Touch-screen | SIEMENS |

| 3 | Labeling engine | GERMAN NOVEXX |

| 4 | Frequency converter | Delta |

| 5 | check bottle sensor | Japan KEYENCE |

| 6 | Check opaque label sensor | German Leuze |

| Check opaque and transparent label sensor | GSU 14B/66.3-S12 | |

| 7 | Main transport motor | JSCC |

| Model | PLM-A & PLM-ALS204 |

| Driving Model | Servo system & German Novexx |

| Label material | Self-adhesive sticker, opaque or transparent label |

| Yield(pcs/min) | 50-200pcs/min |

| Suitable label size | L:10-300mm,H:10-250mm |

| Suitable bottle size | Diameter: 28-100mm , H:30-260mm |

| Voltage | 110V/220V/380V |

| Machine size | 1800(L)× 800(W)× 1500 (H) mm |

1. Printer device, printing date and batch number on labels.

2.Turntable

If machine not connect with production line, suggest choose turntable more convenient for operation.

3.GERMAN NOVEXX Labeling engine

① Machine with two years warranty;

② Supply operation training for client workers ;

③ If with quality problem, provide technical support and supply wearing parts timely .

④ Range experienced engineer come to client company for installation;