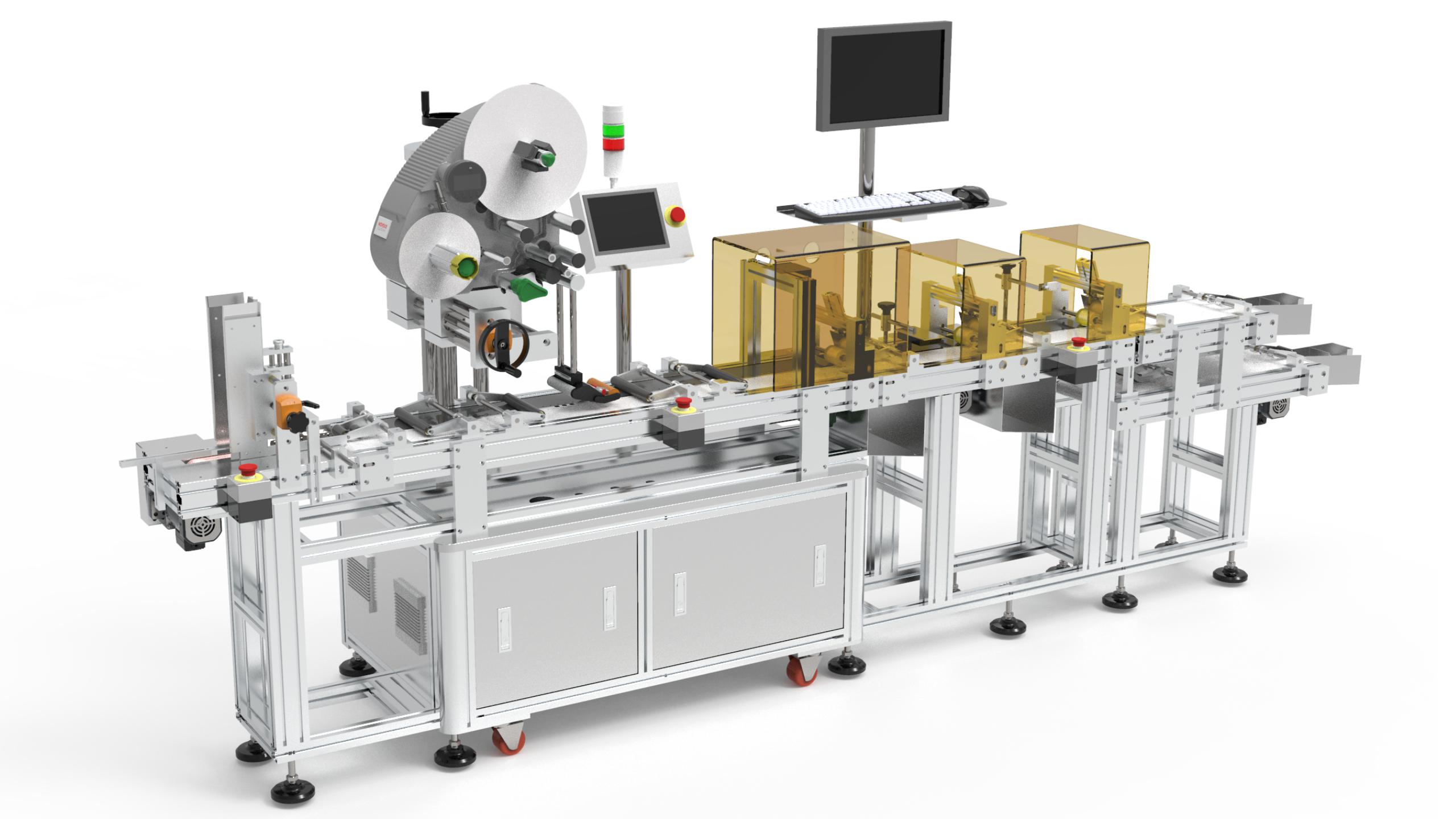

Hang Tag Label Applicator Solution

SKILT tag label applicator have made for Nike, Adidas, Levis, Muji, UA, ZARA, CK project, for more information, Pls ref case.

MACHINE FUNCTION INTRODUCTION

1.Feeder: Paging device, can put about 500pcs tag one time, delivery out one by one;

2. Labeling: When tag delivery to the labeling position, past RFID sticker on tag surface directly;labeling engine use German Novexx ALS204, for demending 24/7 countinous operation, tandem function for non-stop production , IP65;

3. RFID detection: If RIFD label on tags can not reading, eliminate substandard tag to the bottom collection box ;

4. Visual Inspection: If labeling accuracy more than ±1mm, eliminate substandard tag to the bottom collection box ;

5. #1 collection conveyor : With counter function for stack collection ;

6. #2 collection conveyor: When #1 reach to the counter number, will auto switch to the #2 conveyor , convenient for worker take tags out.

| No | Name | Brand |

|---|---|---|

| 1 | PLC control system | SIEMENS |

| 2 | Touch-screen | SIEMENS |

| 3 | Labeling engine Servo motor |

Panisonic |

| 4 | Labeling engine Drive |

Panisonic |

| 5 | Frequency converter | DELTA |

| 6 | pheck tag sensor | Japan KEYENCE |

| 7 | Check label sensor | German Leuze |

| 8 | Main transport motor | JSCC |

| Model |

PM-DPM-A |

| Driving Model | Servo motor & German NOVEXX |

| Label material | Self-adhesive sticker, opaque or transparent label |

| Yield(pcs/min) | 50-200pcs/min |

| Suitable label size | L:10-300mm,H:10-250mm |

| Suitable tag size | L: 30-300mm , W:30-200mm |

| Voltage | 110V/220V/380V |

| Machine size | 2200(L)× 800(W)× 1600 (H) mm |

1.Visual inspection system & take-out:

After labeling, tags delivery to visual inspection system, camera work and detect labeling accuracy,unqualified tag will been take out into waste hopper

2. Auto collect device:

With double layer conveyor collection device and conveyor back-flow collection device for optional, rather convenient for worker operation ;

3. Labeling engine German NOVEXX

① Machine with two years warranty;

② Supply operation training for client workers ;

③ If with quality problem, provide technical support and supply wearing parts timely .

④ Range experienced engineer come to client company for installation;